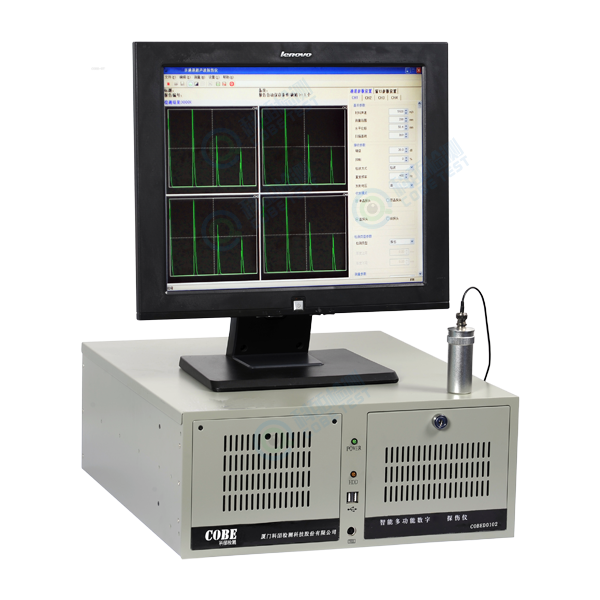

COBE-UT21XX Intelligent Digital Multi-channel Ultrasonic detector uses the most advanced digital electronic technology and ultrasonic technology.With beautiful design,steady performance, easy operation and favorable price features .

The instruments can be widely used for titanium tube, zirconium tubes, seamless steel tubes, welded gas and oil pipelines, nonferrous metals, ferrous metals and some other non-metallic pipes, bars, plates ,and the rail automatic (or semi-automatic) non-destructive ultrasonic testing.

Features

◆Independent transmitting channel and switched receiving channel. Casual combination and recycle operation are all available.

◆With own R&D Digital equipment, powerful function

◆Simple configuration, and flexible connection towards the hardware, and 128 channels testing available via various Communicating junction modes.

◆Motor control and other I/O ports reservation is available on the condition that the testing projects needs is satisfied.

◆Each channel has three gates, alarm gate, tracking gate, self locking gate;

◆Complete alarm function, to meet different kinds of needs of the automatic detection system

◆Use of advanced alarm circuit technology which is effective to inhibit the outside interference, strong capacity of resisting disturbance, can improve the reliability of the alarm.

◆Software is modularized ,and can according to your need to be configured.

◆Advanced instrument circuit design and process design , reliable performance, steady operation.

◆File editing function: can storage, invocation, play back and print the testing conditions and flaw wave form, then form the test report .

◆Communication function : via TCP/IP protocol to realize the communication of lower computer and the upper monitor. In this case, we are capable to realize the control via this detector or the upper monitor through the cable network or wireless network

◆Software: continuously upgraded. The OEM testing software is available to meet different testing requirements

Main Technical Data

Gain | 0-100dB,step 0.1dB |

Detection channels | 4, 8,12,16,20,24, 32 |

Operation mode | Single probe transmitter and receiver, dual probe transmitter and receiver |

Scan mode | A、B、C type scan |

Surplus Sensitivity | ≥65dB |

Resolution | ≥36dB |

Dynamic range | ≥42dB |

Scan range(steel longitudinal wave) | 0~6000mm |

Frequency range | 0.5~20MHz |

Repetition frequency | 100Hz~10KHz adjustable |

Vertical linearity | ≤3% |

Horizontal linearity | ≤1% |

Gate setting | Each channel has three gates, alarm gate, tracking gate, self locking gate |

Delayed (marking) alarm | split in two,delayed time :0.5~10S,step: 0.1S |

Testing conditions and flaw wave form | Quantity unrestricted,invocation,wave replay、wave communicate、wave print |

Test report | Automatic generate(WORD 、EXECL) |

Parameter storage | Detection state parameters、echo pattern、DAC curve and remark information etc. |

Clock Type | Inner, outer CLOCK |

Encoder | 50-1024 (Optional) |

Detector mode | positive, negative, bi-directional, radio frequency (RF) |

Peak memory | Can choose echo peak memory display,background peak wave can be in a different color represents. |

SA、PA、RA、% | Real-time display |